We are delighted to welcome you to visit 3D MASTER and whether you are new to 3D printing or just looking to improve your knowledge, we are very happy to have you here. . Most of us have heard of, or know some degree about, the potential of 3D printing. But with this guide we will provide the most complete information about the history of printing, the actual 3D printing process, print materials and the best applications of 3D printing technology. We hope you find this one of the most comprehensive, most comprehensive 3D printing resources available to help you improve your skills.

Are you ready? We will start now!

3D printing technology - also known as rapid prototyping - has been advertised on the internet a lot. Some believe it is true. Others think that this is a hyper-fiction promotional product that exists around this exciting technology. So what is 3D Print actually? And who will use this technology? and how does it apply?

Overview of 3D Printing Technology

3D printing technology includes a wide range of processes and technologies that provide the ability to produce details and products from different materials. Basically, all technological processes have in common the way production is performed, the process of filling the layers of additives, which is in stark contrast to traditional production processes such as molding. The application of 3D printing technology is growing day by day, and it penetrates deeply into the fields of industry, manufacturing plants and consumer industries. Most of the world's most respected researchers in the field of technology agree that, just today, we are beginning to really see the potential of 3D printing. 3D MASTER It is a trusted source for 3D printing, bringing you the latest news, the most overview, development and applications as they emerge in this exciting field. This review is intended to provide you with an insight into the technology, manufacturing process, materials, or history, scope, and benefits of this technology.

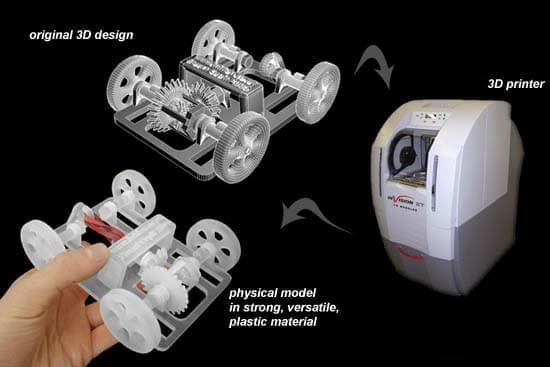

3D printing technology is the process of creating physical models (real samples) from digital models (3D design files on a computer) automatically through 3D printers.

What is 3D printing?

There are different ways to print an object using 3D printing. We will know about it in the guide below. 3D printing brings two basic ideas: the manipulation of objects in digital modeling and the production of new models by rapid prototyping.

Digital model

+

Rapid prototyping

This technology has had more impact on human history lately than any other field. Think of a light bulb, a steam engine, or something like a car or plane, which is not to mention the rapid development of websites around the world. These technologies have made our lives better and more diverse in a number of ways, opening up new avenues of choice, but often take a long time, sometimes even several decades, before appearing by the breakthrough of this technology.

3D printing technology is believed to have great potential to become a technology leader. 3D printers are widely available on many television channels, newspapers and large online social networks. In fact, 3D printers have decided to replace it so that it will replace the traditional production process, revolutionizing the design process, applying it to science, technology, economics, politics, society, population, environment, security for our daily life like?

Basically, to distinguish the principle behind 3D printing technology is the process of producing additives. And this is really the key because 3D printing is a completely different method based on advanced technology. Build up layers of materials to create product models. This is different from any of the traditional production techniques available.

There are some limitations of traditional production. But the world of manufacturing has had to change, and the automation of machining, molding requires the use of machinery, industrial robots to complete.

For many applications of the traditional design process and production process, there are still limitations that can not be overcome such as the cost of expensive cutting tools, machinery, fixtures, etc. can lead to 90% of the original material used wasted.

In contrast, 3D printing is the process of creating an object directly, by cascading layers of material in different ways depending on the technology used in 3D printing. The simple concept of 3D printing for anyone trying to understand this concept is that 3D printing is like building some things with Lego blocks automatically.

3D printing technology enables the promotion and promotion of innovation in thinking, the freedom to design new ideas, a cost-effective and time-saving process. The product details can be specially designed to avoid assembly requirements with complex geometric shapes or high-performance features without the need for additional costs. 3D Printing is also emerging as a high-performance, energy-efficient, environmentally-friendly, energy-saving, 90% print media that meets all standards during operation, It has a stronger texture than traditional materials.

In recent years, 3D printing has made further progress into the typical industry and into the manufacturing process by making the technology more accessible to smaller companies or fish. human. In a number of larger areas, a multinational corporation of size and economy owns a 3D printer, many small 3D printers cost less than $ 1000. This has opened the playing field for many technologies. Objects can be joined, and exponentially increased in all areas, more and more systems, materials, applications, services are being introduced.

The 3D printing process is as follows:

Create 3D CAD models

Create 3D designs in STL format,

cut STL files into aligned sections on Z axis if using small format printers

Build model (one) layer on top of previous layer

Clean and complete the object

3D Modeling (CAD Model Creation): First, the object is modeled using a computer-aided design, 3D modeling using software such as Solidworks, ProE, Zbrush. , Sketchup, etc. Designers can either use a pre-existing CAD file or create a new one for modeling purposes. This process is identical for different types of rapid prototyping techniques.

Convert to STL format (Conversion to STL format): Different 3D software uses different algorithms to represent the 3D object (Solid part), to establish consistency - STL format (stereolithography) has been applied as the standard of the modeling industry. fast. This form is the locus of the triangular planes that intertwine with each other representing the surface of the object in three dimensions. Since the STL format uses planar triangles, it does not show curved surfaces correctly. Increasing the number of triangular faces can improve the smoothness of the curved surface but will increase the file size. Large, complex details will require a lot of time for pre-processing and STL format development. Therefore, designers have to weigh the time, file size and accuracy to get the best STL file.

Slice the STL file: In this step, an STL preprocessor program is built, some programs are available and most allow users to adjust the size, position and orientation of the file. form.

Determining the direction of placement is important for a variety of reasons:

- The nature of the pattern will change with the direction of fitting. For example, the sample will be weaker and less accurate in the Z direction than in the XY

direction. - The model orientation determines the printing time of the model. It is therefore best to place the shortest object in the Z direction of the device to reduce the number of layers thereby shortening the print time.

- Each layer has a thickness ranging from 0.016mm to 0.7mm ... depending on different technology.

The program also creates a supporting material structure during the printing process (called material support). It supports useful features of the model, such as the beamless portion; inner pore and thin wall. Each 3D printer manufacturer offers its own 3d printing software.

Layer by layer: This is the main step of the rapid prototyping process, using one of the various techniques (RP techniques). The system builds layers of materials from: polymers, liquid resins, paper, metal powders ... Most are automated, with little human intervention.

Clean up and finish: This is the final step of the process, this step involves removing the auxiliary parts (mentioned in step 3). Prototypes may require cleaning and surface treatment by: sanding, coating to improve the aesthetics of the sample after 3D printing.

(Collected by 3D MASTER)