In the era of Industry 4.0, 3D scanning and reverse engineering have become crucial technologies, especially in the field of industrial machinery maintenance and repair. This article will take you through the basic concepts and practical applications of these technologies.

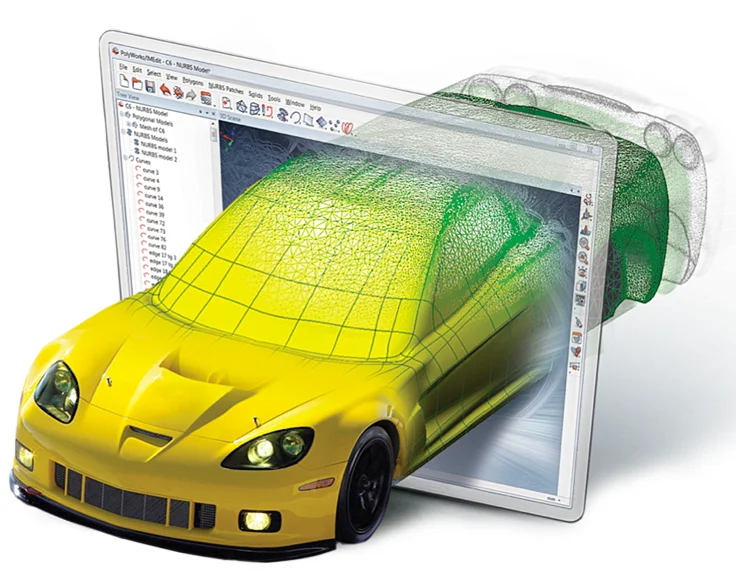

3D scanning, also known as "scan 3D," is a technology aimed at creating a digital model of a three-dimensional object or environment. This process typically utilizes laser scanning or structured light scanning devices to gather information about the shape and structure of the object.

Reverse engineering is the process of analyzing an existing product or system to understand its structure, function, and operating principles, and then creating a new design based on the obtained information. This method is often used when there is no original design documentation or when there is a need to improve, reproduce, or repair a product.

Reverse engineering techniques play a crucial role in understanding the structure and function of components in industrial machinery maintenance. Rapid prototyping is the process of quickly creating a physical copy of a product or model.

When combining reverse engineering and rapid prototyping, we can:

Quickly Provide Solutions: Reverse engineering helps understand the problem, and rapid prototyping facilitates the deployment of solutions flexibly and efficiently.

Design New Models Based on Analysis: Data obtained from reverse engineering provides fundamental information for designing new models through rapid prototyping.

Several powerful reverse engineering software tools are used in the industry to analyze and create 3D models from collected data. Here are some popular software options in the field of reverse engineering:

Integrates 3D scanning technology to create accurate CAD models.

Supports various scan data types, from point clouds to machine learning-based images.

Widely used in reverse engineering and manufacturing.

Converts images into 3D models.

Supports integration with various scanning devices.

Creates models from captured images.

Converts scan data into CAD models.

Used in research and product development.

Converts scan data into diverse 3D models.

Provides editing and optimization tools for models.

Used in manufacturing and maintenance industries.

Supports model creation from point cloud data and 3D scanning.

Provides powerful model editing tools.

Used for reverse engineering and simulation.

Free and open-source.

Supports model creation from scan data and point clouds.

Widely used in design and graphics communities.

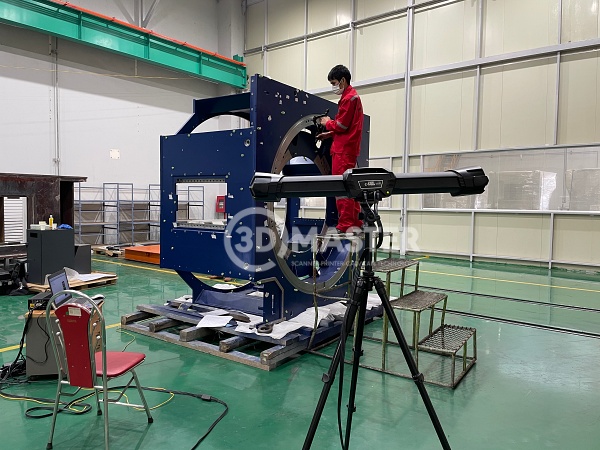

The process of 3D scanning and reverse engineering in industrial machinery maintenance and repair is a modern method that helps engineers and manufacturers grasp detailed information about machine components, enabling a better understanding of the structure and operation of the machinery. Here are some important applications of this process:

3D scanning can create accurate 3D models of machinery or components, aiding in assessing the condition and identifying cracks, damages, or signs of wear.

Reverse engineering allows engineers to understand the structure of machinery, helping them determine the cause of a malfunction and propose effective repair solutions.

Based on information from 3D scanning, engineers can perform reverse engineering methods to improve performance or optimize machine components.

When original components are no longer available, the reverse engineering process can be used to create accurate replicas, aiding in maintaining and extending the lifespan of machinery.

When components are no longer in production, the reverse engineering process can help restore and reproduce those components.

3D Master not only provides conventional 3D scanning and reverse engineering services but also offers diverse and unique solutions for various industries. From creating accurate models in machine manufacturing to applications in quality inspection and maintenance, 3D Master has set a new standard in this field.

Beyond the industrial sector, 3D Master's 3D scanning services have expanded into areas such as healthcare, electronics, and even art. Digitizing bodies within seconds not only supports the creation of custom medical products but also opens up new possibilities in e-commerce, where customers can explore 3D products in detail from a distance.

In particular, 3D Master has demonstrated the crucial role of 3D scanning technology in the preservation of cultural heritage and art. Creating precise replicas of artworks and historical landmarks not only helps preserve cultural value but also contributes to the exploration and education of our heritage.

With the uniqueness and diversity of its 3D scanning services, 3D Master is not just a partner in reverse engineering but also a source of inspiration for creativity and development in various industries.

Website: [https://3dmaster.com.vn](https://3dmaster.com.vn)

Hotline - Zalo - LINE - Telegram - WhatsApp - Viber - Kakaotalk: +84 982 089 198 | 0986333960

Email: cuong3dmaster@gmail.com | hung3dmaster@gmail.com | tech3dmaster@gmail.com