With the ability to print from various material layers, 3D plastic printers are emerging as a leading technology, conquering various fields. Whether you have caught up with this trend or are wondering which 3D plastic printer is suitable for beginners, and whether buying a used 3D plastic printer is advisable, 3D Master is here to answer your questions now!

Advantages:

Heat Resistance: ABS exhibits good heat resistance, allowing the product to withstand high temperatures without deformation.

Durability and Impact Resistance: ABS has impact-resistant properties and good durability, resulting in high-strength products.

Easy Machining: ABS can be machined by cutting, drilling, and grinding, facilitating the creation of complex-shaped and detailed products.

Disadvantages:

Shrinkage: ABS tends to shrink when cooling, leading to the appearance of cracks or deformation if the cooling process is not well controlled.

Strong Odor: The 3D printing process with ABS can produce a strong odor, especially in poorly-ventilated environments.

Advantages:

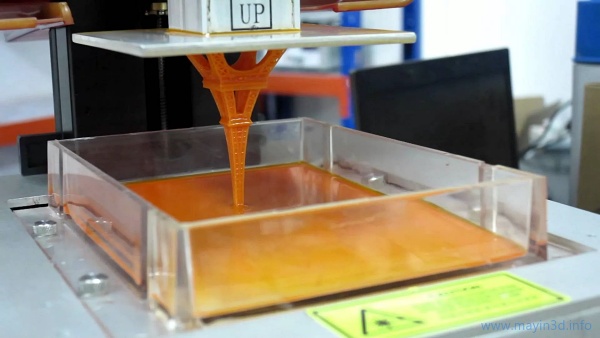

High Detail: Resin 3D printers often have the capability to create very small and precise details, surpassing some printers using PLA or ABS.

Excellent Surface Finish: Products printed with resin usually have a smooth and beautiful surface, requiring minimal post-processing.

Ability to Print Complex Shapes: Resin typically has high tolerance and can produce products with complex shapes.

Disadvantages:

High Cost: Resin is usually more expensive than PLA or ABS, increasing the overall cost of the 3D printing process.

Strict Working Process: The 3D printing process with resin requires strict temperature and light management to avoid uneven curing or shrinkage.

Advantages:

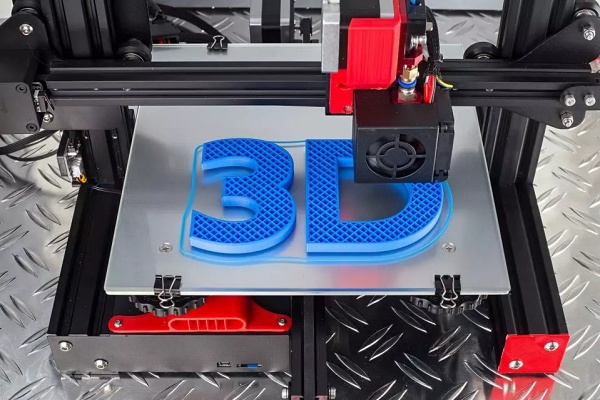

Wide Material Compatibility: DMF 3D printers can use various plastic materials.

Ability to Print Large Products: Some DMF 3D printers come in large sizes, enabling the production of large models and products.

Ease of Use and Maintenance: DMF 3D printers are typically user-friendly and easy to maintain, suitable for both beginners and large-scale production businesses.

Disadvantages:

Lower Precision: Compared to some industrial 3D printing technologies like SLA or SLS, the precision of DMF 3D printers may be lower.

Less Smooth Surface Finish: Products printed from DMF printers may have a less smooth surface compared to other 3D printing technologies.

The prices of 3D plastic printers can vary significantly depending on various factors, including quality, size, features, and brand. Below is a price classification to give you a general overview:

| No | 3D Plastic Printer Type | Price (USD) | Note |

| 1 | ABS 3D Plastic Printers | From 300 to 3000 | |

| 2 | Resin 3D Printers | From 500 to 5000 | |

| 3 | Industrial DMF 3D Printers | From 500 to 3000 |

Opting for a cheap used 3D printer, thinking it will save costs, has left many regretful. Used 3D printers often degrade, and increased vibrations can significantly impact the quality of 3D prints. Reduced accuracy and smoothness of the product are direct results of these issues, making the 3D printing process inefficient.

In addition, finding precise spare parts can become a challenging task, posing a significant challenge for maintenance and repairs.

Moreover, outdated printer software can complicate the 3D printing process. Updates and new features are often unavailable for older printers, reducing flexibility and performance.

In the market for cheap 3D printers, there are various options such as self-assembled resin 3D printers and DIY DMF 3D printers. However, many of these printers are assembled from rudimentary components, lacking quality assurance and stability.

Most cheap, non-branded 3D printers come with risks regarding quality and post-sales support. The use of self-assembled components often faces difficulties in ensuring stability and accuracy.

Cheap 3D printers from unreliable sources often do not guarantee quality post-sales services. Technical issues may lead customers to deal with a lack of timely technical support.

Deciding to purchase a 3D printer solely based on low prices might provide temporary comfort but could lead to unforeseen consequences, making repairs troublesome. Once a 3D printer encounters problems, seeking timely support becomes a challenge, and unexpected costs can frustrate users.

In a business context, if a 3D printer fails while processing customer orders, the risk of having to compensate for lost orders becomes significant. Inability to handle orders accurately and promptly can result in not only monetary losses but also damage to the business's reputation.

Considering the risks of buying a low-quality 3D printer that jeopardizes both operation and cost, investing wisely from the beginning is advisable. Choosing the right 3D printer requires careful consideration and depends on various factors. Below, we will introduce some of the best 3D printers:

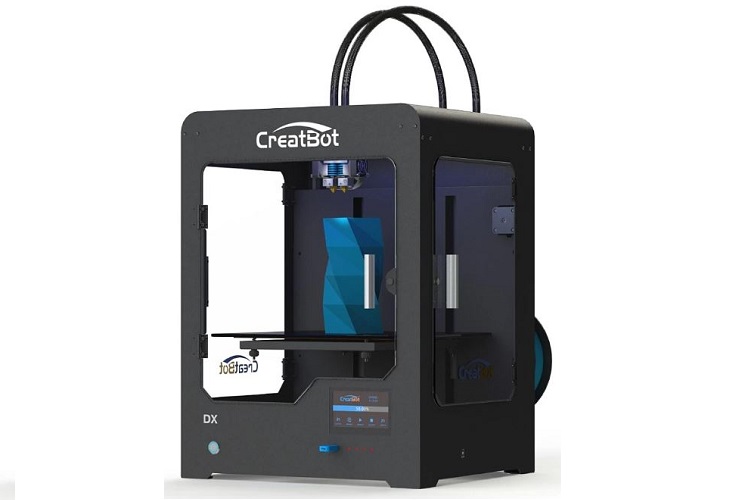

Unique Smoothness and Detail:The DX/DX PLUS plastic 3D printer uses advanced printing technology to produce unique smoothness and details.

Excellent Precision: With a modern engine and control system, the DX/DX PLUS 3D printer provides high precision, ensuring that products are reproduced accurately as in the original design.

Fast Printing Speed: DX/DX PLUS is designed to optimize printing speed while maintaining quality.

Diversity in Material Usage: DX/DX PLUS plastic 3D printers usually have the ability to use various plastics such as PLA, ABS, PETG, and many other engineering plastics.

Unique Material Flexibility: The Resin F160 3D printer from CREATBOT in China is a unique solution in the field of filament 3D printing, using FDM/FFF technology. The special feature of F160 is its flexibility in using various printing materials.

Large Print Size: With a sample size of 160*160*200 mm, the F160 provides enough space to create a variety of complex and diverse 3D products.

Flexible Printing Speed: The F160 printer offers flexible printing speeds from 70 to 300 mm/s, allowing users to adjust according to specific project requirements.

High Resolution: With a printing resolution of 0.05 mm and accuracy in the Z-axis up to 1.25 μm, the F160 ensures that the printed product has high smoothness and detail.

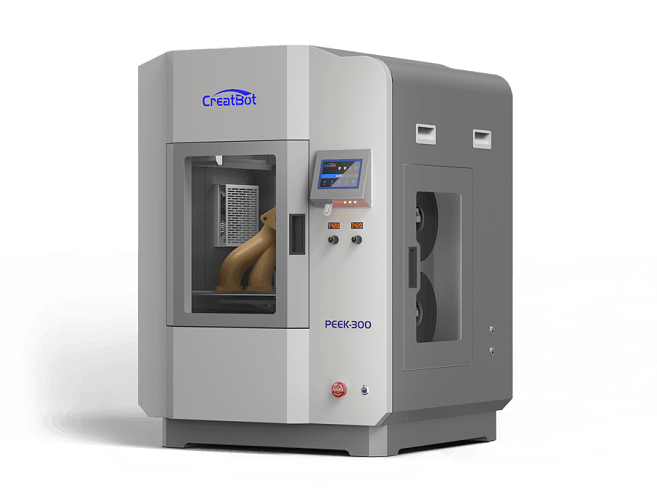

High-Speed PEEK-300 3D Printer

PEEK Material Characteristics: The PEEK-300 3D printer primarily focuses on printing with PEEK material, a high-temperature-resistant, fire-resistant, and high-stiffness plastic.

Efficient Cooling System: The printer often comes with a specialized cooling system, aiding in temperature control and ensuring a stable printing process.

Advanced Control Software: The PEEK-300 typically utilizes advanced control software, providing users with a convenient experience and efficient production management.

>>>>>>>>>> SEE MORE: 3D PRINTERS | Genuine - Reliable - Affordable

3D Master Company takes pride in being a reputable and trustworthy entity in the 3D printing industry. With years of experience, we are recognized as a reliable partner for individuals and businesses seeking high-quality and efficient 3D printing solutions.

What sets 3D Master Company apart is the commitment to product quality and service. We are distributors of leading 3D printer models in the market, ensuring that our customers receive modern equipment that meets all creative needs.

If you are looking for a reliable partner to purchase a 3D printer, choose 3D Master Company. We will accompany you on the creative journey and provide you with the best 3D printing experiences.