Although 3D scanning is common, the accuracy, data, and usability vary significantly between different providers. This article analyzes the core reasons and how to choose a technically sound 3D scanning service.

In recent years, 3D scanning has become a familiar technology in mechanical engineering, manufacturing, heritage preservation, education, and research. From digitizing mechanical details and reconstructing artifacts to reverse engineering products without blueprints, 3D scanning offers superior speed and accuracy compared to traditional measurement methods.

However, a reality that puzzles many engineers and businesses is that, for the same object and the same 3D scanning requirements, the results vary significantly between different companies. Some produce smooth, accurate data ready for CAD; In some cases, the model is distorted, lacks detail, and cannot be used for reverse engineering.

The most common mistake when evaluating 3D scanning services is assuming that quality depends entirely on the scanner. In reality, the equipment is only part of the problem. 3D scanning is a comprehensive technical process where every small step directly affects the final accuracy of the 3D model.

The difference in 3D scan results stems from three core factors: equipment capability, implementation process, and human experience. If even one of these three factors is lacking or weak, the 3D scan data will hardly meet technical standards.

Not all 3D scanning systems are designed to serve the same purpose. Some devices are suitable for scanning small details in a laboratory setting, but they may not guarantee stability when scanning large objects or complex surfaces. Conversely, high-end industrial 3D scanning systems are designed to maintain consistent accuracy over large areas, controlling errors under real-world environmental conditions.

This difference explains why, even with 3D scanning, data from different units can have varying levels of detail and reliability. If the equipment is not suitable for the real-world problem, the resulting 3D model will only be illustrative and will not meet technical standards.

3D scanning is not simply a surface scanning operation. A proper 3D scanning process must include establishing a reference system, controlling cumulative errors, managing point data, and post-processing. For large or geometrically complex objects, even small misalignments can lead to significant overall errors.

Many 3D scanning companies prioritize "scanning as quickly as possible," neglecting necessary technical control steps. This results in unstable output data, making it difficult to use for reverse engineering or technical verification. Conversely, companies with well-structured 3D scanning processes prioritize error control, even if it means extra processing time.

With the same 3D scanning system, the results can differ drastically between experienced and inexperienced operators. 3D scanning engineers not only operate the machine but also need to understand the object's geometry, surface materials, data usage objectives, and potential risks during the scanning process.

The ability to read data, detect discrepancies, and make timely adjustments is something that can only be acquired through real-world projects. This is why many businesses, after experimenting with 3D scanning in various places, realize that "even with the same 3D scan, the results are incomparable."

3D scanning only truly proves its value when the data obtained can be converted into a CAD model for design, manufacturing, or inspection. If the 3D scan data is not accurate enough or not processed correctly, the reverse design process will face many difficulties, even requiring starting over from scratch.

Companies specializing in 3D scanning always closely integrate data scanning and reverse design. This ensures that the 3D model is not only correct in shape but also meets technical standards, allowing for long-term use throughout the product's lifecycle.

3D Master implements 3D scanning as a holistic engineering solution, where scan data is always closely linked to the project's practical application. Before each 3D scan, the engineering team thoroughly analyzes the output requirements, such as measurement, reverse engineering, or modification, thereby selecting the appropriate equipment and process from the outset, avoiding mass scanning followed by subsequent reprocessing.

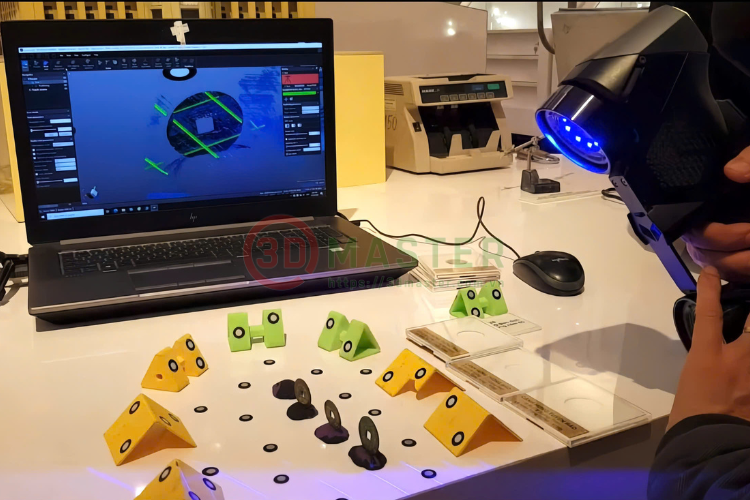

3D Master's difference lies in its Creaform 3D scanning system, which boasts micrometer-level accuracy, allowing for stable data acquisition even with large details or complex geometries. The 3D scan data is highly reliable and ready for direct use in CAD modeling, discrepancy comparison, and engineering analysis.

3D Master Scans 3D Models Using Handyscan Creaform 3D Scanners

With over 10 years as the official distributor of Creaform in Vietnam and experience in implementing numerous 3D scanning projects in mechanical engineering, industry, and heritage, 3D Master delivers 3D models with superior accuracy and applicability compared to mass-produced 3D scanning services.

3D scanning becomes extremely crucial when the original drawing is no longer available, when improvements or accurate reconstruction of the original shape are needed, or when the scanned data is used as the basis for production and technical inspection. In these cases, even very small errors can significantly impact the entire project.

Choosing a truly capable 3D scanning provider will help businesses avoid the risk of rework, saving time and costs in the long run.

Although 3D scanning is the same, the results can vary greatly between different companies, because 3D scanning is not just about technology but also about experience and technical processes. Suitable equipment, standardized procedures, and a competent engineering team are three key factors determining the quality of the final data.

If you are looking for an accurate, stable 3D scanning solution ready for reverse engineering or manufacturing, 3D Master is the company that can partner with you and advise on the right solution for each specific problem.

-->> See more: Reliable and high-quality 3D scanning services at 3D Master

Hotline - Zalo - LINE - Telegram - WhatsApp - Viber - Kakaotalk: +84 982 089 198 | 0986333960

Email: cuong3dmaster@gmail.com | hung3dmaster@gmail.com | tech3dmaster@gmail.com

Website: https://3dmaster.com.vn