Errors in 3D scanning stem from the equipment, environment, and data processing procedures. This article analyzes the core causes and how 3D Masters control 3D scanning errors to ensure high accuracy for engineers and businesses.

3D scanning is increasingly widely used in mechanical engineering, industry, shipbuilding, heritage, and engineering research. However, not every 3D scanning project produces the desired accurate data. In fact, errors in 3D scanning directly affect reverse engineering capabilities, measurement accuracy, discrepancies in comparisons, and the overall project efficiency.

Many businesses only realize the problem when 3D scan data cannot be incorporated into the design, or when CAD models are misaligned or have incorrect dimensions compared to reality. At that point, the cost of repairs, rescans, or additional measurements is far more expensive than controlling the error from the start.

Errors in 3D scanning don't stem from a single cause but are a combination of various technical factors throughout the scanning and data processing process.

First, there are errors from the 3D scanning equipment. Each 3D scanner has limitations in accuracy, stability, and the ability to maintain error across the entire model. Common 3D scanning systems usually produce good results in small areas, but when the object size is increased, the accumulated error increases rapidly and becomes difficult to control.

Next, there are errors from the 3D scanning environment. Ambient light, background vibration, temperature, surface reflectivity, and material color all directly affect data quality. Especially in 3D scanning projects outside the factory, outdoors, or on large objects, the environment is a very common cause of error.

Another important cause is error in the 3D scanning process. The choice of scanning method, machine movement strategy, reference frame, and how data is controlled during scanning greatly affects overall accuracy. Improper 3D scanning can produce visually appealing data but with dimensional inaccuracies.

Finally, there are errors in post-scanning data processing. Inaccurate data merging, excessive smoothing, or improper model creation will increase errors even if the original data is of good quality.

In many engineering projects, errors of just a few hundredths of a micromet can lead to assembly deviations, mismatched parts, or the inability to reproduce the work. Especially with reverse engineering from 3D scans, inaccurate data will render the entire CAD model unusable.

Errors in 3D scanning not only affect a single detail but also spread to subsequent steps such as design, simulation, measurement, and manufacturing. Therefore, controlling 3D scan errors is not a secondary requirement, but a core criterion of a professional 3D scanning project.

Many people believe that simply scanning slower or multiple times can reduce 3D scan errors. In reality, if the equipment and process are not suitable, repeated scanning can even make the data more confusing and difficult to process.

Controlling errors in 3D scanning requires a synchronized combination of high-precision equipment, standardized technical procedures, and the practical experience of the implementation team. This is why the same object can yield vastly different 3D scan results from different units.

3D scanning equipment plays a fundamental role in error control. High-precision 3D scanning systems utilize laser technology, self-compensating error capabilities, and dynamic tracking to ensure stable data, even when scanning large objects or complex surfaces.

Micrometer-level accuracy allows 3D scan data to be used directly for reverse engineering, discrepancies comparison, and engineering analysis without the need for multiple manual adjustments. This is especially important in high-tech industrial and engineering projects.

At 3D Master, 3D scanning is not implemented as a mass scanning process but is approached as a comprehensive engineering solution. Before each 3D scanning project, the engineering team thoroughly analyzes the data's intended use, from measurement and reverse engineering to modification or remanufacturing.

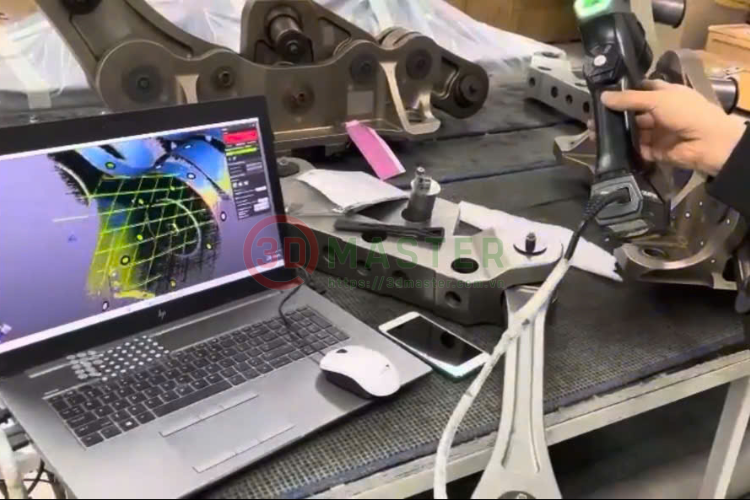

Based on output requirements, 3D Master selects the appropriate 3D scanning equipment and establishes measurement and error control procedures from the outset. The genuine Creaform 3D scanning system used by 3D Master boasts high accuracy down to the micrometer level, ensuring data stability across the entire model, even with large objects or complex geometries.

Furthermore, experience in implementing hundreds of 3D scanning projects in mechanical engineering, industry, heritage, and education allows 3D Master to proactively address factors causing errors from the environment and post-scan data. The processed 3D scan data is always ready for reverse engineering, measurement, and practical applications without requiring extensive rework.

3D scanning errors need to be carefully controlled when the original drawing is no longer available, when precise reconstruction of the actual shape is required, or when 3D scan data is used directly for production. In these cases, even small errors can lead to significant risks in terms of cost and schedule.

3D scanning errors are a core technical issue, directly affecting data quality and the overall project efficiency. Understanding the source of errors and choosing the right specialized 3D scanning provider is crucial for success. With a systematic approach, high-precision 3D scanning equipment, and years of practical experience, 3D Master effectively controls 3D scanning errors, providing reliable data for engineers and businesses.

If you, as an engineer or business, need highly accurate 3D scan data for reverse engineering, measurement, or manufacturing, please contact 3D Master directly for advice on the most suitable and optimal 3D scanning solution for your specific project.

-->> See more: Reliable and high-quality 3D scanning services at 3D Master

Hotline - Zalo - LINE - Telegram - WhatsApp - Viber - Kakaotalk: +84 982 089 198 | 0986333960

Email: cuong3dmaster@gmail.com | hung3dmaster@gmail.com | tech3dmaster@gmail.com

Website: https://3dmaster.com.vn