In the era of rapidly developing technology, 3D scanning and reverse engineering have become important tools in many industries. 3D scanning is the process of using scanning devices to collect surface data of an object, creating an exact digital copy of that object. Reverse engineering, on the other hand, is the process of recreating a 3D model from scan data, in order to create new designs or improve existing products. These two technologies not only save time and costs but also ensure high accuracy in production.

3D scanning and reverse engineering have wide applications in many fields, from medical, automotive, aviation, to industrial manufacturing. In the plastic box manufacturing industry, this technology helps create accurate models, thereby ensuring the quality of the final product.

Using 3D scanning in reverse engineering brings many significant benefits. It allows manufacturers to accurately reproduce existing parts or products, helping to optimize the manufacturing process while minimizing errors.

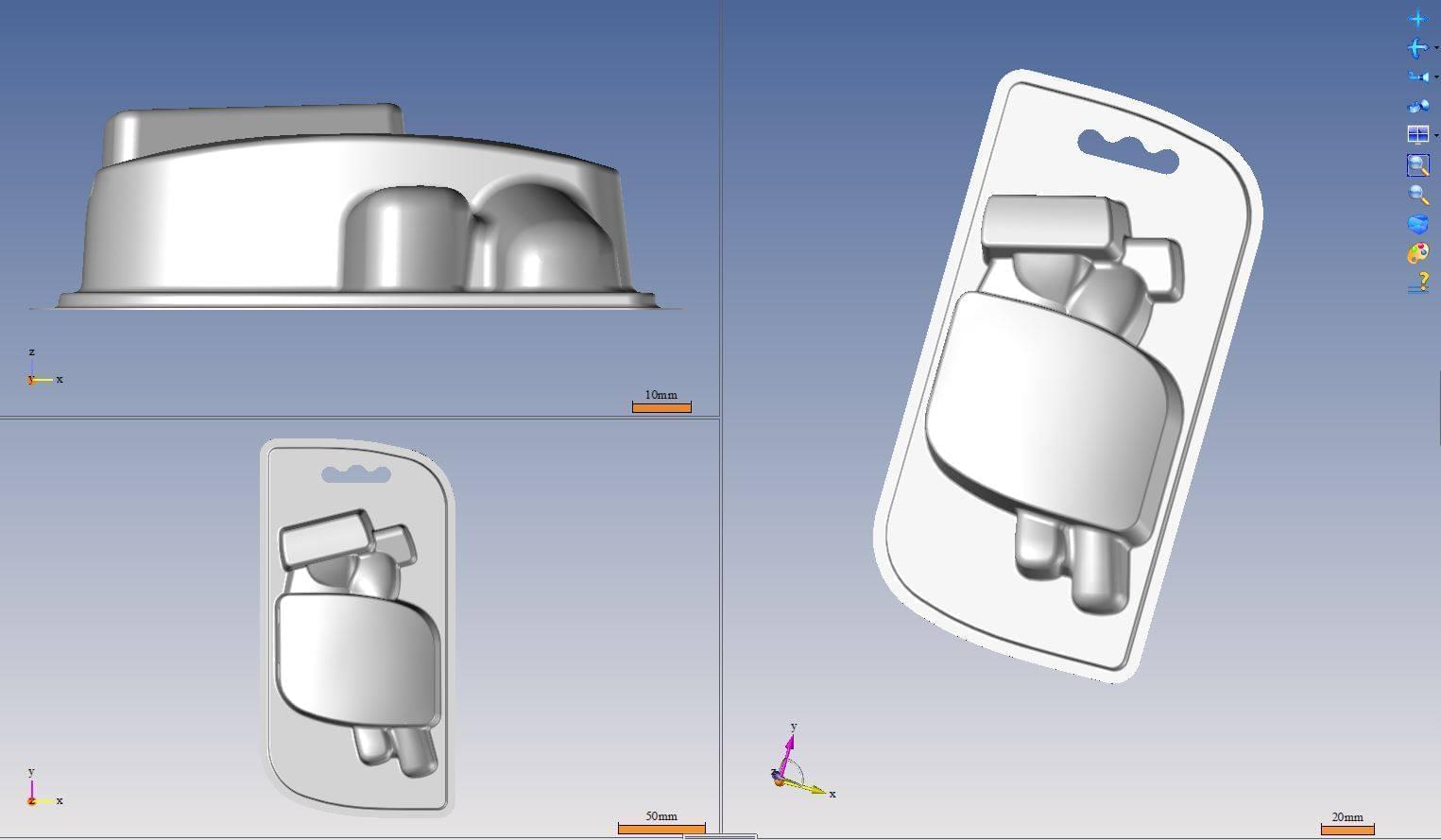

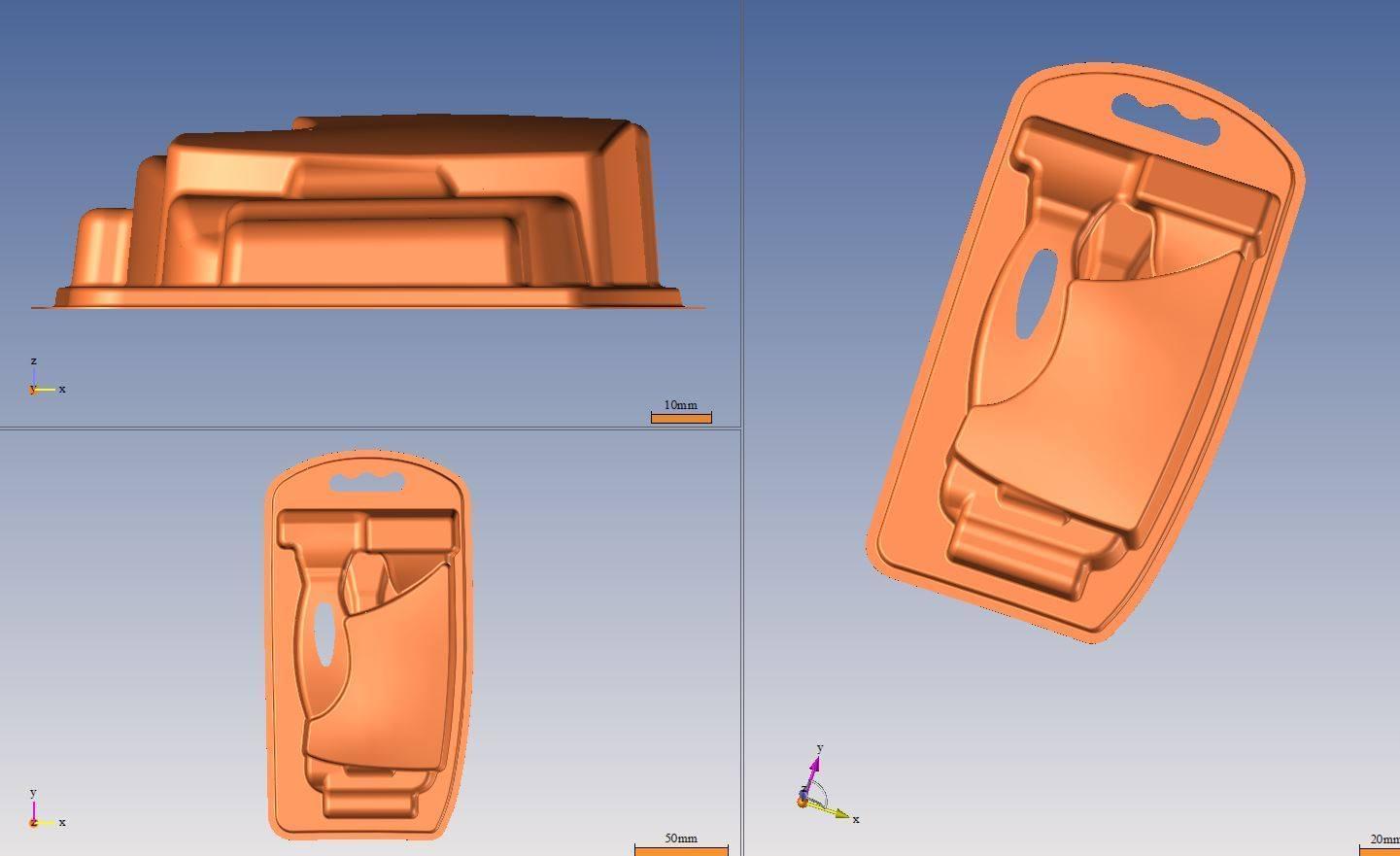

Vacuum molded plastic boxes are one of the products commonly used in the food, pharmaceutical, and consumer goods industries. Vacuum molding technology allows the production of complex shaped plastic boxes, ensuring durability and high aesthetics.

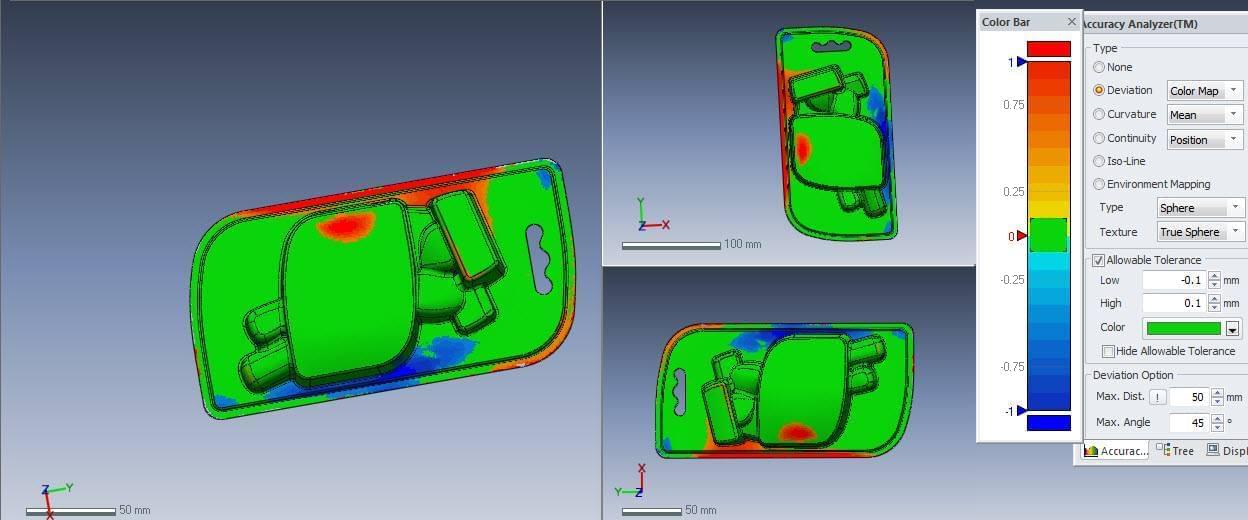

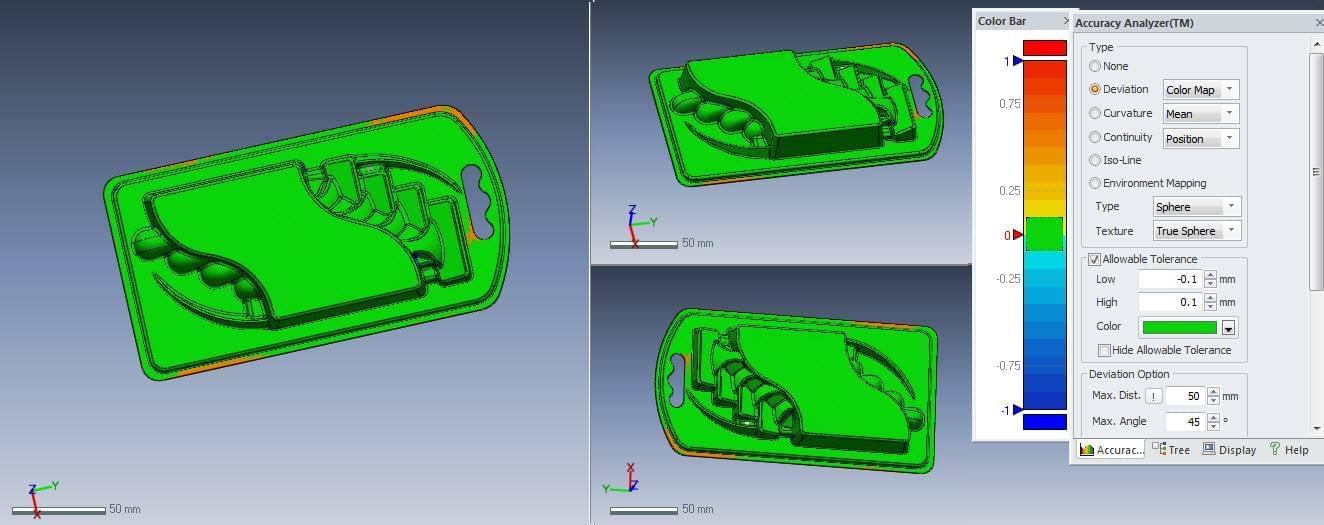

Reverse engineering plays an important role in the production process of vacuum molded plastic boxes, helping to reproduce box models with high precision, thereby improving product quality and increasing production efficiency.

>>>>> See more: Quality 3D Scanning Service at 3D Master

Save Time and Costs: 3D scanning helps optimize the manufacturing process by shortening design time and minimizing costs associated with trial production.

Ensure High Accuracy: Compared to traditional methods, 3D scanning provides much higher accuracy, helping products achieve optimal quality without the need for many adjustments.

3D scanning and reverse engineering are indispensable tools in modern manufacturing, especially in creating vacuum molded plastic box models. With outstanding benefits in terms of accuracy, time and cost savings, this technology is gradually becoming an inevitable trend in the manufacturing industry.

Website: https://3dmaster.com.vn

Hotline - Zalo - LINE - Telegram - WhatsApp - Viber - Kakaotalk: +84 982 089 198 | 0986333960

Email: cuong3dmaster@gmail.com | hung3dmaster@gmail.com | tech3dmaster@gmail.com