Replace large, damaged or obsolete parts accurately and avoid errors with a handheld 3D scanner

Replace large, damaged or obsolete parts accurately and avoid errors with a handheld 3D scanner

In modern manufacturing environments, replacing large, damaged or obsolete parts requires high precision and efficiency. To ensure that the replacement part perfectly matches the technical requirements and integrates smoothly into the existing system, businesses need to avoid common mistakes. The following article will provide an overview of the process and modern solutions to optimize the part replacement process.

1. Challenges When Replacing Large Parts

Replacing large parts is difficult due to:

- Complexity of shape: Parts with complex structures require precise measurements to ensure the fit of the new part.

- Requirement of perfect integration: The replacement part needs to fit perfectly into the installation environment and ensure optimal performance.

- Design and Manufacturing Process: Designing an accurate CAD model from real-world data requires detailed data collection, otherwise it will cause errors in the final product.

2. Advanced Methods of Data Collection

In order to replace parts efficiently, accurate data collection is a prerequisite. There are two main methods:

2.1. Traditional Method

- Advantages: Using rulers, compasses, calipers or images for simple measurements such as the distance between two points.

- Disadvantages: This method is prone to errors when measuring large and complex shaped parts, resulting in incomplete and inaccurate data.

2.2. Modern Measurement Equipment

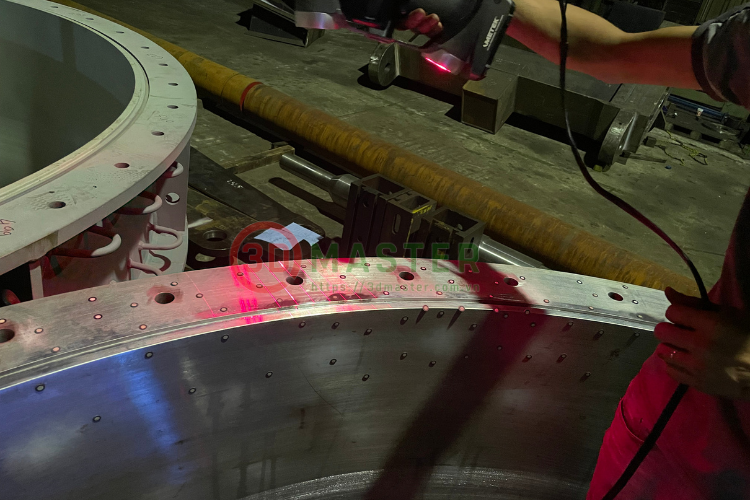

- Handheld 3D Scanner: 3D scanning technology allows the collection of all the size and shape data of the part in a single measurement. This not only saves time but also ensures high accuracy, regardless of environmental conditions.

- Advantages: Fast measurement, complete data and not affected by the instability of the measuring environment.

3. Data Conversion Process From Scan to CAD

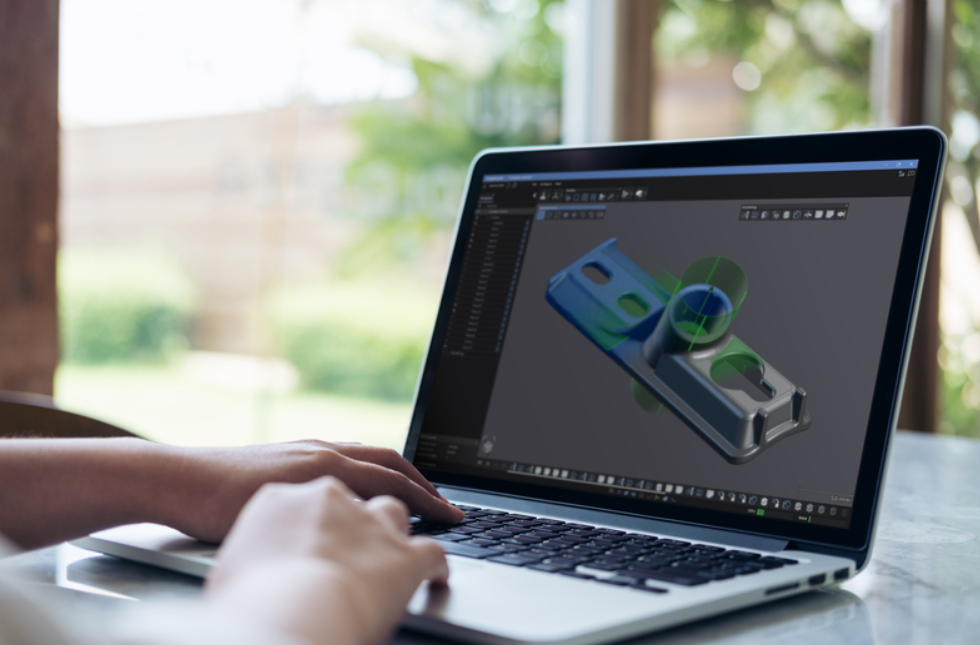

To optimize the design process, modern solutions allow the conversion of 3D scan data into CAD models directly and smoothly. Specifically:

- Scanning and Data Capture: Use a handheld 3D scanner such as the HandySCAN 3D|MAX Series to capture all the geometric information of the part.

- Data Conversion: Creaform's Scan-to-CAD module converts scan data into parameters to CAD software with editable parameters such as dimensions and reference constraints.

- Advantages: Minimize the number of re-measurements, helping to shorten design time and ensure the replacement part fits perfectly into the existing system.

4. Benefits of Applying Modern Solutions

Using modern measurement technology and data conversion software helps businesses:

- Save time: A single 3D scan can collect all the necessary data, eliminating the need for multiple measurements.

- Increase accuracy: Accurate data helps CAD models to be created with minimal errors, ensuring replacement parts have a perfect fit.

- Minimize errors: The automated process from scan to CAD reduces errors due to manual operations.

- Optimize manufacturing processes: Design and manufacture replacement parts quickly, helping to minimize downtime during system operation.

Replacing large, damaged or obsolete parts requires precision and efficiency from data collection to CAD model design. Using handheld 3D scanning devices combined with modern data conversion software is the optimal solution to ensure perfect and efficient replacement parts. Thanks to that, businesses not only reduce production time but also avoid common errors during the replacement process, thereby improving product efficiency and quality.

>>>> See more: Creaform Handheld 3D Scanner / Prestige - Quality - Good price

Contact

Website: https://3dmaster.com.vn

Hotline - Zalo - LINE - Telegram - WhatsApp - Viber - Kakaotalk: +84 982 089 198 | 0986333960

Email: cuong3dmaster@gmail.com | hung3dmaster@gmail.com | tech3dmaster@gmail.com