3D scanning helps to make the maintenance and repair of industrial equipment more accurate by digitizing the actual shape, enabling rapid reverse engineering, and effectively controlling deviations. Discover how 3D Master applies 3D scanning in a factory environment.

In modern manufacturing environments, downtime for industrial equipment repairs always means cost losses. Manual measurement methods or reliance entirely on outdated drawings are often no longer suitable, especially for systems that have been in operation for many years and have undergone many real-world changes. This is where 3D scanning becomes a crucial technological solution in the maintenance and repair of industrial equipment.

Instead of estimating or measuring small parts, 3D scanning allows for the digitization of the entire actual shape of a component, assembly, or equipment system. The data obtained can be used directly for measurement, deviation analysis, and reverse engineering, helping engineers develop more accurate and faster repair plans.

One of the biggest challenges in industrial equipment maintenance is accurately determining the degree of wear, deformation, or damage to a component. Traditional methods often only measure a few individual dimensions, while the overall shape is the determining factor in assembly and operation.

3D scanning allows for the collection of millions of data points across the entire surface of a component. This enables engineers to build a 3D model that accurately reflects the current state of the equipment, instead of relying on the original design drawings, which may no longer be accurate after years of use. This is a crucial foundation for making decisions about repairing, remachining, or replacing components.

When a critical machine part is damaged but the original drawings are unavailable, traditional repair methods are often time-consuming and prone to errors. 3D scanning solves this problem by directly digitizing the remaining part or similar parts that are functioning properly.

The data from the 3D scan is then used for reverse engineering, creating a technical CAD model that can be edited and machined. This makes the repair process of industrial equipment faster, more accurate, and less dependent on old documentation.

After a part is re-machined or replaced, accurate assembly into the old system is a crucial step. Even small deviations can cause vibrations, premature wear, or reduced operational efficiency.

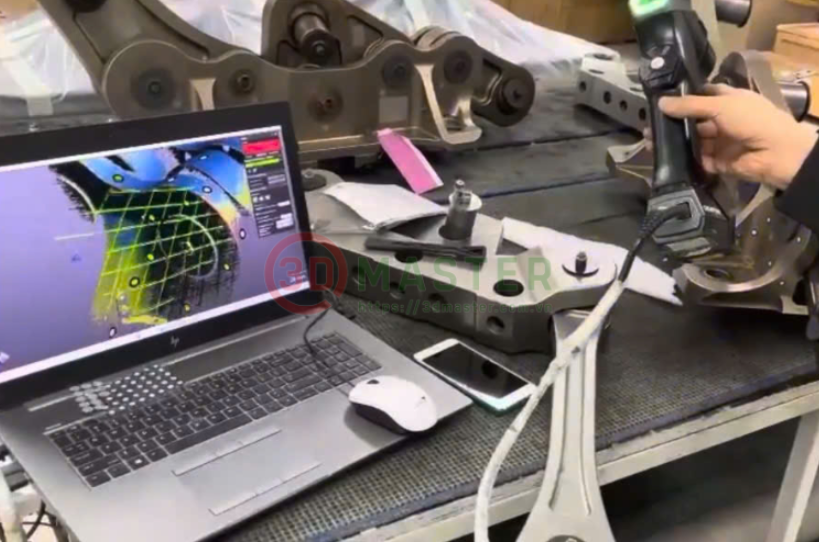

3D scanning helps verify the compatibility between new parts and existing systems by comparing scan data with the design model. Thanks to its visual 3D deviation analysis capabilities, engineers can quickly identify areas requiring adjustment, significantly reducing the time spent on repeated assembly and disassembly tests.

Beyond repair after failure, 3D scanning strongly supports preventative maintenance. By periodically scanning critical parts, businesses can monitor shape changes over time, thereby detecting early signs of wear or abnormal deformation.

3D scan data is stored in stages, building a geometric history of the equipment. This provides a scientific basis for planning maintenance and part replacement before serious failures occur, contributing to improved operational reliability of the entire system.

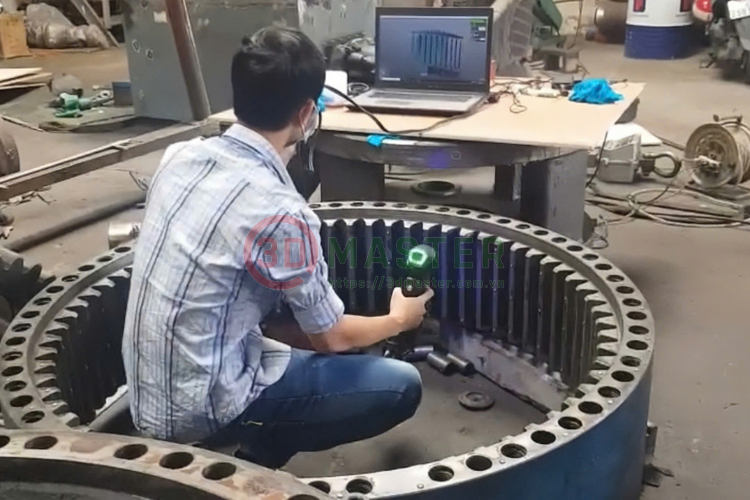

A major benefit of 3D scanning in industrial equipment maintenance is its ability to work quickly and flexibly on-site. Modern handheld 3D scanning systems allow engineers to collect data directly at the factory without disassembling the entire equipment.

Rapid digitization shortens measurement time while providing complete data for reverse engineering and parallel repair planning. As a result, total downtime is significantly reduced compared to traditional processes.

Data from 3D scans only truly becomes valuable when converted into a usable engineering model. Reverse engineering from scan data allows for the accurate reconstruction of the part's geometry, the addition of technical tolerances, and structural optimization if needed.

In industrial equipment maintenance, the combination of 3D scanning and reverse engineering helps businesses be more proactive when replacing components, especially for machines that have been discontinued or for which genuine parts are no longer available.

With extensive experience in implementing numerous factory projects, 3D Master offers specialized 3D scanning services for the maintenance and repair of industrial equipment. The process is designed to ensure that scanned data directly meets the requirements for measurement, reverse engineering, and remachining of parts.

3D Master utilizes a high-precision 3D scanning system suitable for both small parts and large equipment assemblies. The data obtained is highly stable and readily available for use in design and engineering analysis software. This allows businesses to shorten repair time, reduce error risks, and improve maintenance efficiency.

Faro Creaform HandyScan Black Elite 3D scan of thermoelectric gears

Businesses should consider using 3D scanning when equipment has been in operation for many years and accurate blueprints are no longer available, when needing to reconstruct damaged machine parts, or when wanting to check the degree of structural deformation after prolonged use. 3D scanning is particularly useful in industries with large-sized equipment, complex geometry, and high precision requirements.

If your business needs a high-precision maintenance or repair solution for industrial equipment, contact 3D Master for advice on 3D scanning and reverse engineering services tailored to your specific machinery system.

See also: Professional 3D scanning services - best prices at 3D Master

Hotline - Zalo - LINE - Telegram - WhatsApp - Viber - Kakaotalk: +84 982 089 198 | 0986333960

Email: cuong3dmaster@gmail.com | hung3dmaster@gmail.com | tech3dmaster@gmail.com

Website: https://3dmaster.com.vn