3D scanning helps engineers detect assembly errors with micrometer precision, enabling quick inspection, error reduction, and time-saving corrections. 3D Master's industrial 3D scanning solution helps businesses effectively control quality from the very first assembly.

In mechanical manufacturing, machine building, and heavy industry, assembly errors are always a problem that costs engineers a lot of time, money, and effort to resolve. Even a small deviation between parts can cause vibrations, premature wear, or even render the entire system inoperable. Therefore, 3D scanning is becoming a crucial tool that helps engineers control assembly errors more visually, accurately, and effectively than traditional methods.

Assembly errors don't just stem from a single cause. In practice, deviations can arise from machining tolerances, material deformation, wear and tear of parts over time, or differences between design drawings and the actual product. When assembling many large parts together, these small errors accumulate and become serious problems.

With traditional manual or contact measurement methods, engineers can often only inspect a few isolated points. This makes detecting overall deviations in the assembly difficult, especially with complex structures or large parts.

3D scanning is a technology that uses non-contact scanning equipment to capture the actual shape of an object as a point cloud or a highly accurate 3D model. 3D scan data accurately reflects the actual geometry of the part or assembly, including deformations that are difficult to detect with the naked eye.

In assembly control, 3D scanning acts as a "digital copy" of the actual product. This allows engineers to directly compare the scanned model with the design drawings, quickly detecting geometric deviations, misalignment, warping, or incorrect assembly.

The biggest strength of 3D scanning is its ability to collect data on the entire surface, rather than just measuring individual points. This gives engineers a comprehensive view of assembly errors.

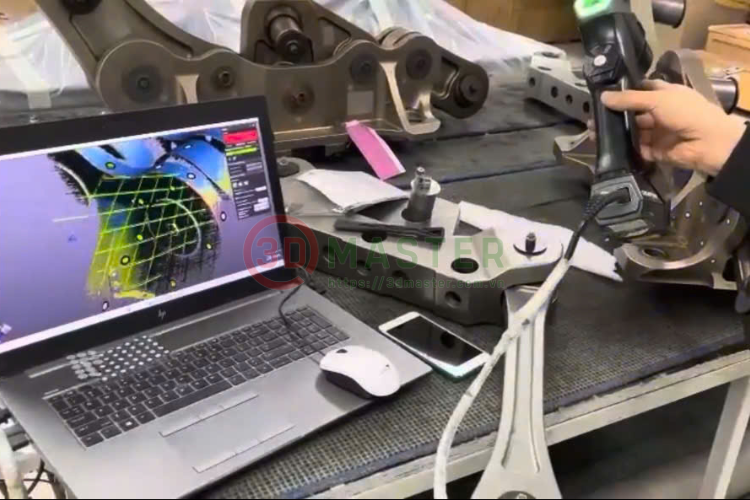

After scanning, the 3D scan data is fed into specialized software to compare it with the original CAD model. The system automatically displays the areas of deviation, the degree of deviation, and the direction of deviation from the design. This allows engineers to easily identify the cause of the error, which part or stage in the assembly process is at fault.

Unlike dry numerical measurements, 3D scanning displays deviations using visual color maps on a 3D model. Engineers can immediately see areas exceeding tolerances, incorrectly assembled areas, or deformed surfaces, allowing for faster and more accurate corrective actions.

3D scanning is not only used in the final stage but is also highly effective in inspecting each assembly step. Engineers can scan each component before complete assembly to ensure each stage meets requirements. This minimizes the need to discover errors after assembly, preventing costly disassembly and rework.

For large projects, 3D scanning also helps store geometric data from each stage, creating technical documentation for quality control and maintenance later on.

In machinery modification or old equipment restoration projects, original drawings are often missing or do not accurately reflect the current state. This is where 3D scanning proves most effective. By directly scanning the actual equipment, engineers can accurately determine the dimensions, shape, and existing deviations to design suitable replacement parts.

Thanks to 3D scanning combined with reverse engineering, assembling new parts into the old system becomes more precise, reducing the risk of misalignment or incompatibility.

Instead of spending days measuring, testing, and manually adjusting parts, 3D scanning significantly shortens assembly inspection time. Engineers can detect errors early, address them correctly and to the necessary extent. This not only reduces downtime but also saves on rework or replacement costs.

In the context of businesses increasingly focusing on optimizing efficiency, 3D scanning has become a solution offering clear economic benefits.

3D scanning is now widely used in many fields such as precision mechanics, mold making, shipbuilding, aerospace, energy, and heavy industry. These industries all share the common requirement for high assembly accuracy, which is difficult to control using traditional measurement methods.

The application of 3D scanning helps improve product quality, reduce technical risks, and increase long-term operational reliability.

3D Master provides high-precision industrial 3D scanning services suitable for assembly inspection, CAD comparison, and reverse engineering. 3D Master's team of experienced engineers understands the real-world challenges in manufacturing, providing optimal 3D scanning solutions for each specific project.

Our state-of-the-art 3D scanning equipment ensures fast, accurate data collection without damaging the surface of the parts, meeting the stringent requirements of engineering companies.

3D Master scans gears using a Metrascan Creaform 3D scanner.

3D scanning is particularly suitable when engineers need to inspect complex assemblies, large-sized equipment, modify old machinery, or when the required accuracy exceeds the capabilities of manual measurement. Applying 3D scanning at the right time minimizes risks and improves the overall efficiency of the production process.

3D scanning is not just a measurement tool, but also a comprehensive solution that helps engineers detect and reduce assembly errors scientifically and effectively. Implementing 3D scanning allows businesses to shorten inspection processes, reduce correction costs, and control product quality more effectively, especially in fields requiring high precision.

If you, as an engineer or business, are facing difficulties in controlling assembly errors, please contact 3D Master directly for advice on the most suitable 3D scanning solution.

-->> See more: Professional, high-quality, and affordable 3D scanning services at 3D Master

Hotline - Zalo - LINE - Telegram - WhatsApp - Viber - Kakaotalk: +84 982 089 198 | 0986333960

Email: cuong3dmaster@gmail.com | hung3dmaster@gmail.com | tech3dmaster@gmail.com

Website: https://3dmaster.com.vn