There are seemingly normal technology testing sessions, but they create an experience that makes the entire engineering team… pause for 5 seconds to admire. The story of 3D digitizing a tea table with the Creaform HandySCAN BLACK+ Elite machine at 3D Master is such an example.

Imagine you are assigned the task of rebuilding a tea table model in its original shape, every curve of the table edge, every rounded edge of the leg. It looks simple, but to measure it manually? You can spend all day and still get it wrong.

Many interior engineers have shared that objects with “few corners but many curves” such as tea tables, decorative chairs, rounded wooden furniture… are the most difficult to build. A little mistake will cause the form, shape, and proportion to be lost.

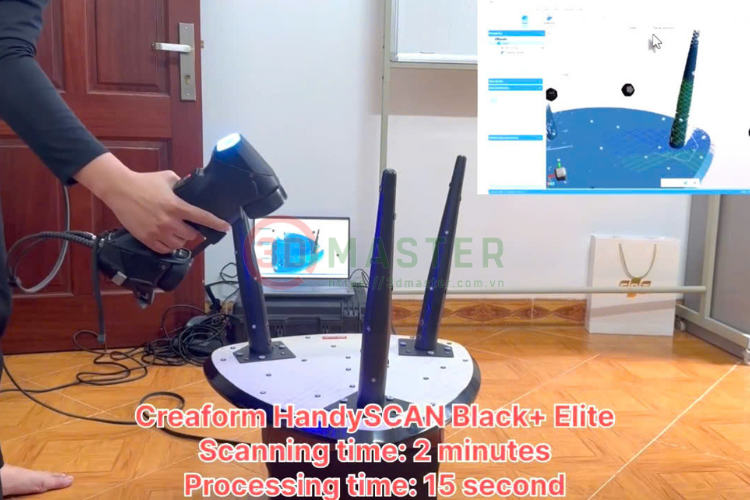

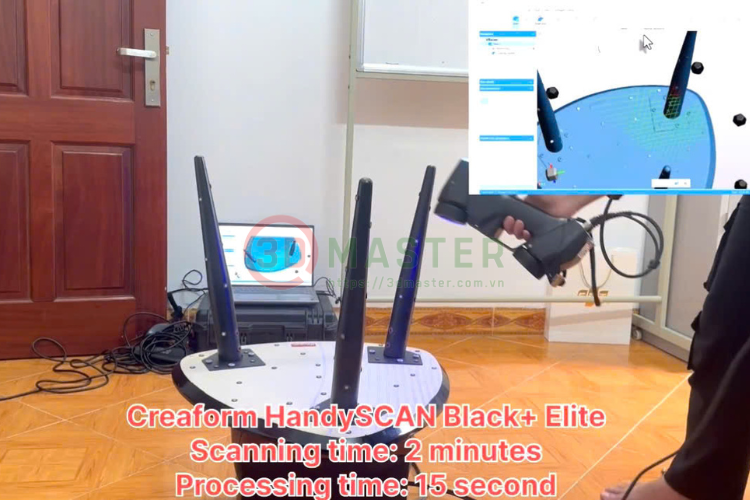

It only took 2 minutes for the complete 3D scan to appear on the screen:

No gloss coating, no special processing, no repeated repetition. This is why HandySCAN 3D digitization technology is at the top of the high-end segment.

Creaform HandySCAN BLACK+ Elite 3D digitizer coffee table

A new employee of 3D Master asked that day: “Why is it so soft and real when scanned quickly?” The answer is simple: Extremely dense point density + good curved surface capture ability + new generation shape reconstruction algorithm.

No few-shot, no studio lighting dependence. HandySCAN BLACK+ Elite uses a green laser to record industrial-standard data, so the scanned model is both “beautiful” and “accurate to the data”.

Conclusion: This is the value of 3D digitization: recreating real objects with an accuracy that the naked eye cannot predict.

It only takes 2 minutes to scan, but the important thing is the next step: rebuilding the CAD model.

From the 3D scan data in mesh form, the 3D Master engineer performs:

When the customer receives the model, they only say one sentence: “Wow, it’s exactly the same down to the micrometer.” That’s the feeling that every design engineer wants.

3D digitization results of tea table

The story of 3D digitization of tea table is just a small example, but it shows how fast the design and manufacturing industry is changing. Previously, manual measurement took a few hours, rebuilding the model took a few days or accumulated errors caused the final product to deviate from its form. But now, 3D scanning takes a few minutes, rebuilding the model takes a few hours and the error is almost zero. 3D digitization technology not only helps speed but also helps confidence. Not "estimate", not "drawing based on experience", but rebuilding based on real data.

It is undeniable that 3D digitization technology is becoming a powerful tool for industries that need to recreate complex shapes: interior, decor, fine art wood, art, crafts, and even restored models. HandySCAN BLACK+ Elite handles all materials and shapes, from large to small, from glossy to matte.

3D Master 3D scans hundreds of furniture sets with Creaform Handyscan

Today's market prioritizes speed, precision and the ability to reproduce details. Whoever masters 3D digitization technology will shorten the entire chain from idea to product. And sometimes, like the example of a coffee table, it only takes 2 minutes to turn a real object into a complete digital model.

If a coffee table can be 3D digitized in 2 minutes, how long do you want your product, larger, more complex, to take? 3D digitization technology allows every process to become lighter, faster and more accurate than ever.

3D Master is a pioneer in 3D technology, accompanying Creaform for more than 10 years. If you need to check samples, build CAD, restore or 3D digitize any product, our team of engineers is ready to support. Call engineer Hung - 3D Master: 0966 086 165, to get direct consultation on 3D digitization services - quick quotes within the day.

Hotline - Zalo - LINE - Telegram - WhatsApp - Viber - Kakaotalk: +84 982 089 198 | 0986333960

Email: cuong3dmaster@gmail.com | hung3dmaster@gmail.com | tech3dmaster@gmail.com

Website: https://3dmaster.com.vn