Can 3D scanning detect post-impact deformation? Learn how to measure geometric deviations, analyze warping, and check detail accuracy using 3D scanning technology.

In industrial environments, mechanical parts, molds, metal structures, or machine components are often subjected to impacts during operation. These deformations can be very small and difficult to detect with the naked eye, but they directly affect assembly accuracy and equipment lifespan. This is where 3D scanning for deformation detection becomes an extremely effective geometric measurement solution.

3D scanning technology allows for the collection of complete surface data of an object in the form of a high-density point cloud. By comparing this data with the original CAD model or pre-impact benchmark data, engineers can accurately determine the location, extent, and type of post-impact deformation.

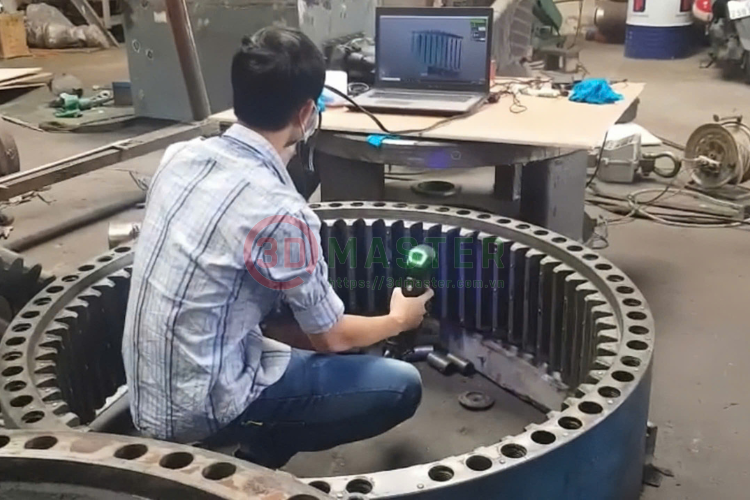

3D scanning for post-impact deformation inspection of steel plates using Faro Creaform Handyscan

Traditional mechanical measurement methods such as calipers, dial gauges, or contact CMMs only check a few isolated points. This results in many small warped areas being missed, especially on complex surfaces.

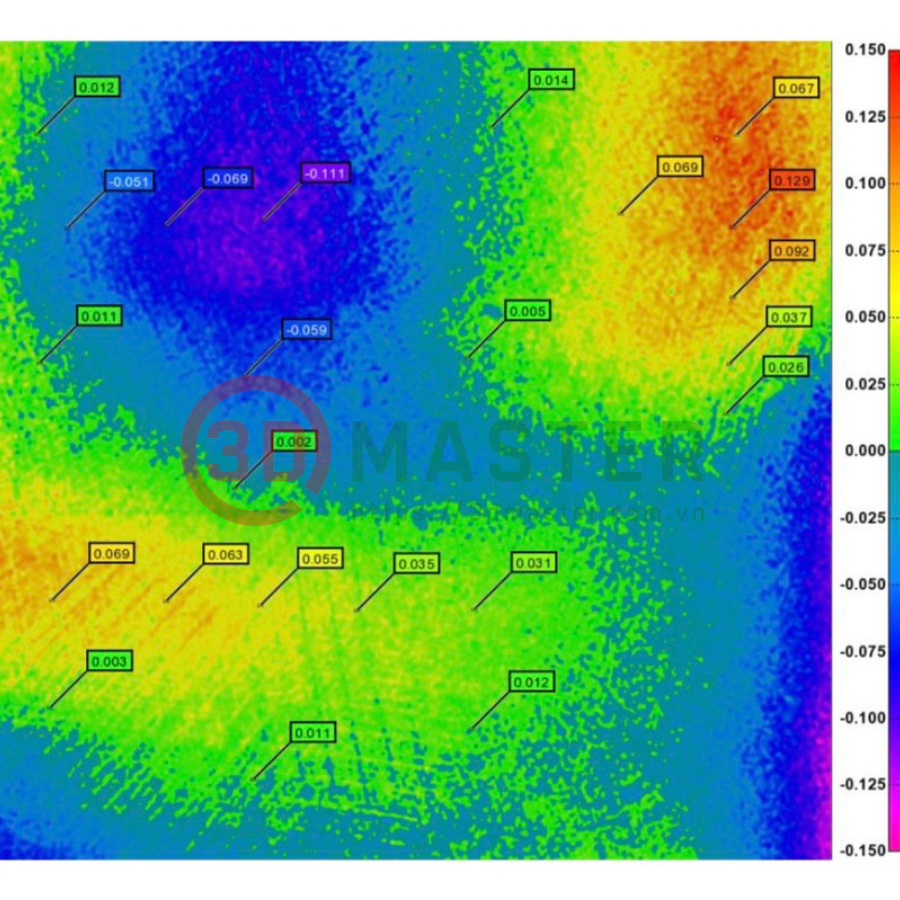

Meanwhile, 3D scanning for deformation measurement allows for analysis of the entire surface geometry. The data is processed using specialized software to create a color map of deviations, visually showing the degree of geometric deviation from the design standard. This gives engineers a comprehensive view instead of relying on just a few localized measurement points.

3D scanning is particularly effective when checking for geometric misalignment on parts with curved shapes, free surfaces, or complex structures that are difficult for contact measuring equipment to access.

Results of a 3D scan of a steel plate after impact

What types of deformation can 3D scanning detect?

3D scanning technology can assist in detecting many different types of deformation after impact or long-term operation. Warping is a common type of deformation on metal plates, machine casings, steel structures, or equipment bodies. 3D scanning helps identify the bent area and the degree of deviation from the original shape. Local deformation often occurs at the point of direct impact. 3D scan data allows for detailed analysis of areas of indentation, bulging, or distortion that are difficult to detect with the naked eye.

Assembly misalignment is also a form of indirect deformation. When a part is impacted, bolt holes, mating surfaces, or positioning markers may become misaligned. 3D scanning supports comparison between CAD models and scan data to assess the extent of this discrepancy.

For 3D scanning to reliably detect impact deformation, the measurement process needs to be carried out systematically. First, engineers scan the entire surface of the part using a high-precision 3D scanning system. The data obtained is processed to remove noise and align to a standard coordinate system.

Next, the scan data is compared with the original CAD design model or the standard pre-impact scan data. The deviation analysis software will create a color map showing the degree of geometric difference on each surface area.

Finally, engineers use these results to assess whether the part is still within the allowable tolerance or requires repair, replacement, or reverse engineering.

When the goal is to analyze the strain of mechanical parts, the accuracy of the 3D scanning equipment plays a crucial role. The smaller the measurement error, the higher the ability to detect small strains. High-end industrial 3D scanning systems can achieve accuracy down to the micrometer level, allowing the detection of very small but significant geometric deviations in precision assembly, molds, or precision mechanical components. If unsuitable equipment is used or the measurement process lacks control, the data obtained may contain errors larger than the actual strain, leading to erroneous conclusions.

S3D Scanning for Strain Inspection of Mechanical Parts

In the mechanical manufacturing industry, 3D strain inspection scanning is used to evaluate molds after impact, inspect machine housings, equipment frames, or cast parts for warping. In industrial maintenance, 3D scanning helps inspect structural deformation after an accident, supporting decisions about repairing or replacing equipment. In the automotive, aerospace, and energy sectors, this technology assists in analyzing geometric misalignments of heavily loaded components, thereby improving operational safety.

3D Master provides 3D scanning services for deformation detection, supporting measurement and engineering analysis for industrial businesses. The company focuses on ensuring measurement data is directly usable for deviation analysis, reverse engineering, and engineering decision-making.

Using genuine Faro Creaform industrial 3D scanners with high accuracy down to the micrometer level, 3D Master is capable of collecting stable data even on complex surfaces and large-scale details. The scanned data is processed using specialized software to create visual deviation maps, assisting engineers in accurately assessing the degree of deformation.

Thanks to its experience in implementing numerous measurement and reverse engineering projects in mechanical engineering, industry, and equipment maintenance, 3D Master offers 3D scanning deformation measurement solutions tailored to the specific engineering requirements of each business.

3D scanning is particularly useful when the part has a complex geometry, is difficult to measure using contact methods, or when a comprehensive assessment of the entire surface is needed instead of a few isolated points. In cases where original drawings are unavailable, 3D scan data can also be used as a basis for reverse engineering, restoring the part's original shape before deformation.

3D scanning is fully capable of detecting post-impact deformation with high detail if implemented using appropriate equipment and accurate measurement procedures. Compared to traditional measurement methods, 3D scanning for deformation analysis provides a comprehensive view of geometric deviations, helping businesses make faster and more accurate engineering decisions.

If your business needs 3D scanning for deformation testing of mechanical parts, molds, or industrial equipment, contact 3D Master for advice on the right measurement solution for your specific requirements.

See also: High-quality 3D scanning services at competitive prices at 3D Master

Hotline - Zalo - LINE - Telegram - WhatsApp - Viber - Kakaotalk: +84 982 089 198 | 0986333960

Email: cuong3dmaster@gmail.com | hung3dmaster@gmail.com | tech3dmaster@gmail.com

Website: https://3dmaster.com.vn