Can 3D scanning accurately scan glossy and dark surfaces? In-depth technical analysis and effective 3D scanning solutions from 3D Master for engineers and businesses.

During the implementation of 3D scanning for manufacturing and research, the most frequently asked question by engineers and businesses is: can 3D scanning be used for glossy and dark materials? This issue is not just a technological one, but directly impacts the quality of the data obtained, the ability to reconstruct engineering models, and the project implementation schedule.

In reality, glossy and dark materials are always considered a “test of capability” for any 3D scanning solution. If the technology and procedures are not handled correctly, the data obtained is prone to noise, missing points, or geometric distortion, rendering the 3D model unusable for engineering purposes.

The nature of 3D scanning technology is to acquire geometric data through the interaction between light and the object's surface. With dark or highly reflective surfaces, this process becomes significantly more complex.

Dark materials tend to absorb light, making it difficult for the sensor to fully capture the reflected signal. Conversely, glossy materials or polished metals reflect light too strongly, causing interference or distortion of the measurement data. This is why many common 3D scanning systems struggle when working with black painted parts, dark engineering plastics, polished stainless steel, polished aluminum, or plated surfaces.

The answer is yes, but not all 3D scanning solutions perform well. The ability to 3D scan glossy and dark materials depends on three core factors: scanning technology, equipment stability, and data processing expertise.

High-end 3D scanning systems using laser or blue light technology with intensity control and error compensation capabilities will deliver significantly superior results compared to cheaper scanners. Furthermore, the data processing algorithm plays a crucial role in eliminating noise and ensuring geometric consistency across the entire model.

In current industrial applications, laser 3D scanning is considered the most effective solution for difficult materials. This technology is not heavily dependent on surface color and maintains high accuracy even in complex lighting environments.

In addition, next-generation blue light 3D scanning systems significantly improve data acquisition on highly reflective surfaces. However, to achieve optimal results, the right equipment must be combined with appropriate measurement and calibration procedures for each material type.

A common mistake is assuming that a good 3D scanner is enough. In reality, the 3D scanning process is the decisive factor in the final data quality.

For glossy and dark materials, engineers need to assess the data's intended use beforehand: measurement, reverse engineering, discrepancy comparison, or remanufacturing. Only then can they select the appropriate scanning method, scanning angle, dot density, and data processing approach. 3D scanning without a clear objective from the outset often results in redundant but inaccurate data, leading to time-consuming corrections later.

In reverse engineering projects, 3D scan data needs to ensure geometric stability and surface continuity to be able to reconstruct the engineering CAD model. With glossy and dark materials, if the data is noisy or missing points, the reverse engineering process will encounter many difficulties and easily lead to errors.

Similarly, in quality measurement, 3D scanning is only truly valuable when the data accurately reflects the actual shape of the part. This requires the 3D scanning system to maintain consistent accuracy across the entire surface, including areas with strong reflection or light absorption.

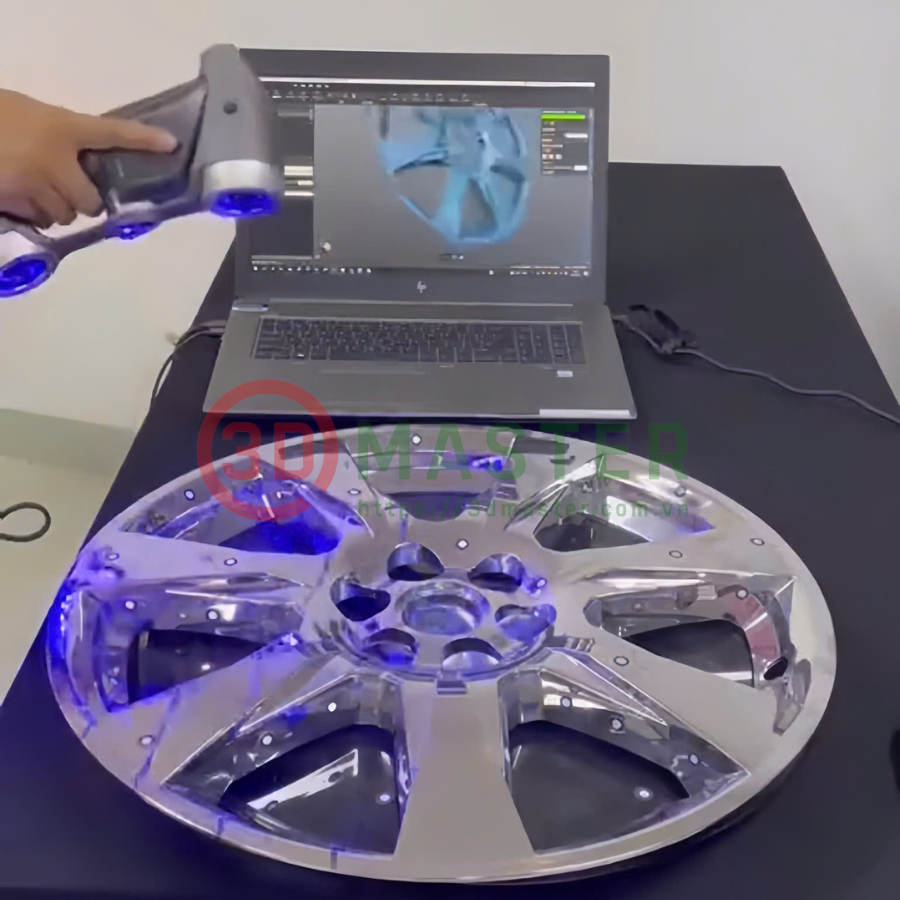

3D Master scans a glossy wheel sample using a Handyscan Creaform 3D scanner

3D scanning of glossy surfaces and dark materials requires control of lighting and data stability right from the scanning stage. At 3D Master, each 3D scanning project is analyzed based on material characteristics and output requirements such as measurement or reverse engineering, in order to select the appropriate equipment and methods from the outset.

3D Master uses genuine Creaform 3D scanning systems, with accuracy down to the micrometer level, allowing for stable geometry recording even with highly reflective metals or dark surfaces. The data obtained can be used directly for CAD modeling, discrepancy comparison, and manufacturing without complex manual adjustments.

Advanced 3D scanning is particularly suitable when working with parts that have difficult-to-measure surfaces, where original drawings are unavailable, or where high accuracy is required. In these cases, choosing the right 3D scanning service not only saves time but also minimizes the risk of technical errors throughout the entire project.

3D scanning can be used for glossy and dark materials, but it is only effective when implemented with appropriate technology and a proper technical process. The difference lies not in whether or not it can be scanned, but in the quality of the data and its usability in design, measurement, and production.

Please contact 3D Master's engineering team directly for advice on suitable 3D scanning solutions for glossy, dark materials and complex technical problems in real-world production.

->>> See more: Reliable and high-quality 3D scanning services at 3D Master

Hotline - Zalo - LINE - Telegram - WhatsApp - Viber - Kakaotalk: +84 982 089 198 | 0986333960

Email: cuong3dmaster@gmail.com | hung3dmaster@gmail.com | tech3dmaster@gmail.com

Website: https://3dmaster.com.vn