Mold Design Training Program:

Design orders for one detail

Training program Design of dies:

Mold design orders for one detail:

Training program on molding CNC machine:

- Introduction: Topsolid software features, graphical interface

- Program Setup Commands

- Select the machine

- Declare the knife position in the knife store

- embryo, embryo, embryo definition

2D Outsourcing: 2D Milling

2D processing methods:

- Analyze the cause

- Analyzing the hole system

- Contuor milling, facing, pocketing, multi pockets

- Practice 2D milling

3D Machining: 3D Milling

3D machining methods

· 3D milling cycles

· Vertical roughing

Finishing cycles

· Z Level

· Constant Scallop

3D Milling Work Orders

Raw processing methods

Finishing methods

Practical 3D milling

| Two axis machining program • Turning X, Z • Roughing cycles • Finishing cycles Commands for machining Analytical tools Facial head, rough outer lathe Clean the outside Groove, Thread, Parting Off Machining |

| Post-Processors Program simulation commands Calculation of processing time Simulate Toolpath Simulate the operation of the machine Simulation of material cutting during machining Port NC program |

4D machining: 4 axis milling

4D milling orders

4 axis Facing

4 axis roughing: 4 axis roughing

Revolve parallel plane

Optimizing the machining program

4 axis Pocketing

Practical programming 4D machining

5D machining: 5 axis milling

- 5 axis drilling: multiple hole drilling in different faces,

swarf machining: tangential milling with surfaces in complex angles,

- 5axis contour: 5 axis simultaneous milling under the road limit,

- 5 axis swept: milling with any surface, with each method has the option of eating knife, the optimal knife that the designer can easily control cutting motion ...

- Optimizing the machining program

Practical programming 5D machining

3-axis CNC milling machine

Overview of CNC machines

Main structure of CNC machine

Turn the machine off, the notes when operating the machine

Main functions on the panel, moving the axis

Calculation method, knife length

Practical hand cutting

Automatic transmission and cutting

5-axis CNC milling machine

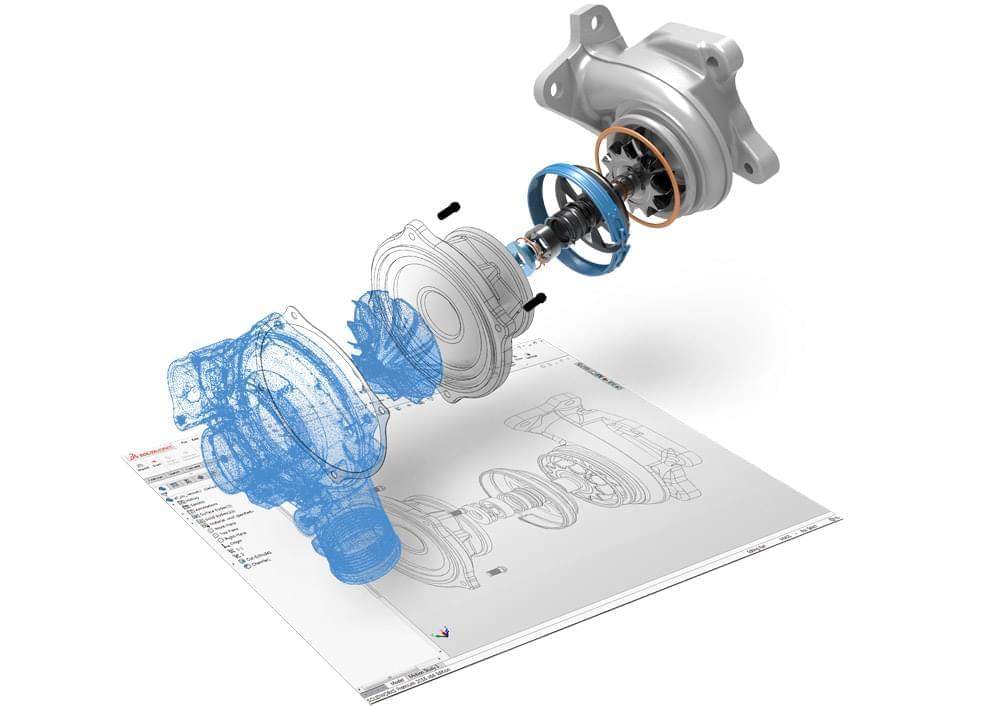

Currently CNC numerical control machines and CNC machines in particular are widely used in mechanical engineering, especially in precision engineering. The application of this technology has brought high efficiency in processing In addition to the three-axis machining technologies, there are technologies that are required to be machined on 5-axis machines, such as complex machining, curved surfaces, not processed. Machine tools are just a tool for implementing technology ideas, the design of technology for machines such as machine tools, CNC machines play a very important role. Improper or improper design of the technology will lead to difficulties in processing, inaccurate products and sometimes product damage. The strong development of CAD / CAM / CAE technology has greatly assisted designers in designing and defining appropriate technology steps. Thus, to be able to manufacture high quality products requires the designer not only to grasp the machining features of each machine, but also to make the process of fabrication technology reasonable.

In the field of mechanical engineering today, especially in the field of precision mechanics, the application of three-axis control machines is becoming more common, but for complex details where the machining center of the part not in a certain direction. In this case, the user can create in detail several processes (in several different directions). At the same time, machines with rollers, counters, graduated heads and tilting heads will be used, which will produce on the surface many different workpieces, so it can be processed in detail. Even if the surface of the complex parts, this will increase the quality of the machined surface and shorten the machining time.

Overview of 5 axis CNC machine

Main structure of 5-axis CNC machine

Turn the machine off, the notes when operating the machine

Main functions on the panel, moving the axis

Calculation method, knife length

Practical hand cutting

Automatic transmission and cutting