3D digitization is becoming a core solution helping automotive manufacturers improve the accuracy of casting inspection, shorten quality control time, and ensure products meet stringent technical standards.

In the automotive industry, aluminum casting plants play a particularly important role as they directly produce parts that affect the performance, safety, and durability of vehicles. Parts such as engine blocks, transmission housings, suspension arms, subframes, and body structures all operate under heavy loads, strong vibrations, and extreme temperature environments. Even a small deviation in geometry or material distribution can lead to assembly errors, reduced lifespan, or serious operational risks.

Therefore, quality control of castings is always a mandatory step requiring extremely high precision. However, as technical requirements become increasingly stringent, traditional measurement methods are revealing many limitations.

In many factories, coordinate measuring machines (CMMs) are still the main equipment for inspecting casting dimensions. However, the nature of this method is to measure at individual, pre-programmed points. This means that only a very small part of the part's surface is controlled.

For parts with complex shapes, many deep cavities, and curved surfaces, measuring only a few representative points cannot fully reflect the overall geometric condition. Surface deviations, localized material shortages, or slight deformations can be completely missed. When errors are not detected early, the consequences are increased rework costs, waste generation, and a direct impact on production progress.

This is why automotive manufacturers are increasingly turning to 3D digital solutions for comprehensive casting inspection.

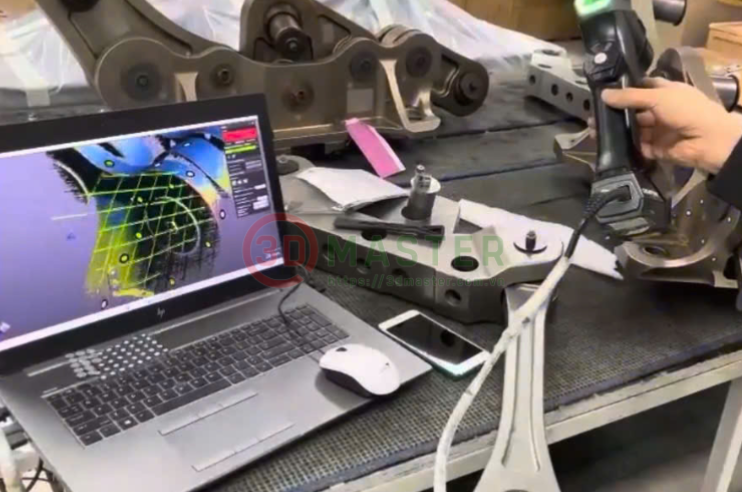

Unlike point-based measurement methods, 3D digitalization allows for the collection of the entire surface shape of a casting in a very short time. Through 3D scanning technology, millions of data points are recorded and recreated into an accurate 3D model of the actual part.

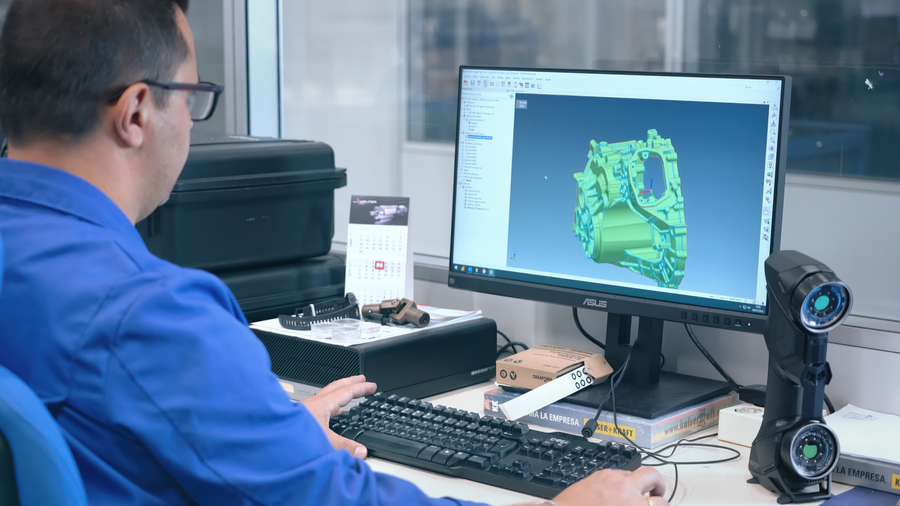

The 3D digital data is then directly compared with the CAD design model. Any deviations in size, shape, or material distribution are clearly shown through a visual color map. As a result, the quality control department can quickly assess the compliance level of each part without performing many complex manual measurements.

More importantly, 3D digitization allows for full geometric inspection, ensuring that castings always have sufficient machining allowance and are within acceptable tolerance limits before moving on to the next stages.

One of the biggest advantages of 3D digitization is its ability to drastically reduce inspection time. Instead of spending hours measuring each point with a CMM, the 3D scanning process takes only a few minutes to collect data on the entire part.

Specialized inspection software allows for rapid data processing, displaying results for comparison with CAD almost instantly. This helps the engineering team detect errors early, make timely decisions, and prevent the continued production of substandard parts.

Shortening inspection time not only increases productivity but also significantly reduces costs associated with scrap, rework, and production line downtime.

Another advantage that makes 3D digitization increasingly popular is its ability to be deployed directly in the production environment. Modern 3D scanners have a mobile design, allowing casting inspection right on the production line without transporting heavy and bulky parts to a separate measurement room.

Dynamic referencing technology helps maintain high accuracy even under conditions of vibration, temperature changes, or harsh foundry environments. As a result, quality control becomes more flexible, responsive, and closer to actual production.

3D digitization not only helps detect defects but also plays a crucial role in improving manufacturing processes. When geometric data is fully collected at every stage, manufacturers can easily analyze deviation trends, identify root causes, and adjust molds, casting parameters, or technological processes.

This proactive approach leads to more consistent product quality, reduces variability between production batches, and ensures every part meets customer technical requirements.

Many major automotive component manufacturers worldwide have adopted 3D digitization as a standard in casting inspection. Scanning entire parts helps them improve dimensional accuracy, enhance surface quality, and shorten product approval times.

In reality, thanks to 3D digitization, many businesses have significantly reduced inspection time, increased quality control output, and improved the reliability of components in critical systems such as engines, transmissions, and chassis.

In Vietnam, 3D Master provides 3D digitization services for inspection, measurement, and quality control in the automotive and manufacturing industries. With a system of 3D scanners meeting measurement standards and specialized analysis software, 3D Master helps businesses inspect castings comprehensively, accurately, and quickly.

3D Master's 3D digitization solution is suitable for many different types of parts, from small parts with complex geometries to large structures, meeting the stringent requirements of modern industrial production.

In the context of the automotive industry constantly raising quality standards, 3D digitization has become an indispensable technology in casting inspection. Controlling the entire geometry, shortening inspection time, and early defect detection helps businesses reduce costs, increase production efficiency, and ensure the highest product quality.

If your business is looking for an accurate, flexible casting inspection solution that suits your real-world production environment, 3D digitization is the strategic choice for now and the future.

Contact 3D Master today for in-depth 3D digitization solutions for casting inspection and quality control in the automotive industry. 3D Master is ready to partner with your business on the journey to raising quality standards and optimizing production efficiency.

See also: Reliable 3D digitization services - good price - high quality at 3D Master

Hotline - Zalo - LINE - Telegram - WhatsApp - Viber - Kakaotalk: +84 982 089 198 | 0986333960

Email: cuong3dmaster@gmail.com | hung3dmaster@gmail.com | tech3dmaster@gmail.com

Website: https://3dmaster.com.vn